Table of contents

- Why Start a Notebook Manufacturing Business in India?

- Startup Cost: A Detailed Breakdown

- 1. Market Research and Feasibility Study

- 2. Business Plan Development

- 3. Legal and Regulatory Compliance

- 4. Setting Up Your Manufacturing Facility

- 5. Sourcing Raw Materials

- 6. Manufacturing Process

- 7. Marketing and Sales Strategy

- 8. Quality Control and Customer Service

- Need Expert Guidance?

- Conclusion

- Frequently Asked Questions (FAQs)

The notebook manufacturing business presents a significant opportunity, especially in a growing economy like India, where education and office supplies are in constant demand. If you’re looking to start your own manufacturing venture, this guide will walk you through the essential steps, ensuring you build a sustainable and profitable business.

Why Start a Notebook Manufacturing Business in India?

- Consistent Demand: Schools, colleges, and offices across India need notebooks year-round.

- Low Startup Costs (Relatively): Compared to many other manufacturing businesses, the initial investment can be manageable.

- Scalability: You can start small and gradually expand your operations as your business grows.

- Local Market Advantage: You can cater to specific regional needs and build a strong local brand.

- Direct to Consumer Potential: You can sell directly to schools, colleges, and stationery shops, maximizing your profits.

Startup Cost: A Detailed Breakdown

The startup cost for a notebook manufacturing business in India can vary depending on the scale of your operation. Here’s a breakdown and tips for minimizing expenses:

- Machinery:

- Paper cutting machine: ₹50,000 – ₹2,00,000 (Consider used machines to save costs).

- Binding machine: ₹30,000 – ₹1,50,000.

- Printing machine (optional, for custom covers): ₹1,00,000 onwards.

- Tip: Research local manufacturers and suppliers for competitive prices.

- Raw Materials:

- Paper (various sizes and qualities): Price varies depending on the market.

- Binding wire/spiral/staples: Relatively inexpensive.

- Cover stock: Price depends on the type and finish.

- Tip: Buy in bulk to get discounts and establish relationships with reliable suppliers.

- Premises:

- Rent for a small workshop/factory: ₹10,000 – ₹30,000 per month.

- Tip: Start with a smaller space and expand as needed. Consider renting in an industrial area to reduce costs.

- Licenses and Permits:

- Business registration, GST registration, etc.: ₹5,000 – ₹15,000.

- Tip: Consult with a local business advisor to ensure you have all the necessary licenses.

- Marketing and Distribution:

- Initial marketing materials, website (optional), transportation: ₹20,000 – ₹50,000.

- Tip: Leverage social media and local networking to promote your business.

Here’s how to Start Your Notebook Manufacturing Business

1. Market Research and Feasibility Study

- Understand the Market:

- Analyze the demand for different types of notebooks (school, college, office, specialized).

- Identify your target audience (students, professionals, artists).

- Research competitor pricing and product offerings.

- Consider seasonal demand fluctuations (e.g., back-to-school season).

- Feasibility Study:

- Calculate the initial investment required for machinery, raw materials, and operational costs.

- Project your potential revenue and profit margins.

- Assess the availability of raw materials (paper, binding materials, etc.).

- Evaluate the logistics of distribution and sales.

- Example: The Indian education sector and the growing corporate sector provides a huge market. Many local notebook manufacturing businesses thrive by supplying to schools and colleges.

2. Business Plan Development

- Executive Summary: Briefly describe your business, its goals, and your target market.

- Company Description: Provide details about your business structure, location, and team.

- Market Analysis: Present your findings from the market research.

- Products and Services: Define the types of notebooks you will manufacture (e.g., spiral-bound, stitched, hardcover).

- Marketing and Sales Strategy: Outline your plan to reach your target audience (e.g., online sales, partnerships with retailers, direct sales to institutions).

- Operational Plan: Detail your manufacturing process, equipment, and raw material sourcing.

- Financial Plan: Include your startup costs, projected revenue, and profit and loss statements..

3. Legal and Regulatory Compliance

- Business Registration: Register your business as a sole proprietorship, partnership, or private limited company.

- Licenses and Permits: Obtain necessary licenses and permits from local authorities.

- GST Registration: Register for Goods and Services Tax (GST) to comply with tax regulations.

- Environmental Regulations: Ensure your manufacturing process complies with environmental regulations, especially regarding paper waste and chemical usage.

💡 Pro Tip: If you want to start a business but have too many doubts, connect with a food business expert from Boss Wallah for guidance – https://bw1.in/1116

4. Setting Up Your Manufacturing Facility

- Location: Choose a location that is accessible for raw material delivery and product distribution. Consider proximity to your target market.

- Machinery: Invest in essential machinery, including:

- Paper cutting machines.

- Printing machines (if you offer printed notebooks).

- Binding machines (spiral, stitched, or perfect binding).

- Packaging machines.

- Raw Materials: Source high-quality paper, binding materials, and packaging supplies.

5. Sourcing Raw Materials

- Paper: Source paper from reputable suppliers, considering factors like quality, GSM (grams per square meter), and cost.

- Binding Materials: Choose durable binding materials like wire, plastic spirals, or thread.

- Packaging: Select eco-friendly and cost-effective packaging materials.

- Image Optimization: Use high-quality images of your products and manufacturing process. Optimize images for web by compressing them and using descriptive alt text.

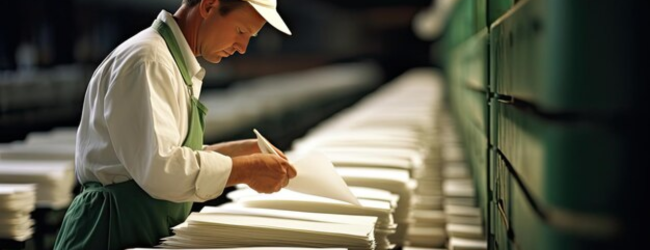

6. Manufacturing Process

- Paper Cutting: Cut large paper rolls into the desired notebook sizes.

- Printing (Optional): Print ruled lines, logos, or designs on the paper.

- Collating: Assemble the paper sheets in the correct order.

- Binding: Bind the assembled sheets using the chosen binding method.

- Covering: Attach covers to the notebooks.

- Packaging: Package the finished notebooks for distribution.

7. Marketing and Sales Strategy

- Online Presence: Create a professional website and establish a presence on social media platforms.

- E-commerce: Sell your notebooks online through your website or e-commerce platforms like Amazon and Flipkart.

- Partnerships: Collaborate with retailers, stationery stores, and educational institutions.

- Direct Sales: Target schools, colleges, and corporate offices for bulk orders.

- Promotional Activities: Offer discounts, promotions, and free samples to attract customers.

- Social Media: Promote your business and products on social media platforms.

8. Quality Control and Customer Service

- Quality Checks: Implement rigorous quality control measures at every stage of the manufacturing process.

- Customer Feedback: Collect and analyze customer feedback to improve your products and services.

- Customer Support: Provide excellent customer support to address inquiries and resolve issues.

Need Expert Guidance?

Starting a business can be challenging, but you don’t have to do it alone! At Boss Wallah, our 2,000+ business experts are ready to provide valuable insights and guidance. Whether you need help with marketing, finance, sourcing, or any other area of any business, our business experts are here to help you succeed- https://bw1.in/1116

Confused about Which Business to Start?

Want to start your own business but unsure which one to choose? Explore Boss Wallah, where you’ll find 500+ courses by successful business owners, featuring practical, step-by-step guides on starting and growing various businesses.

Find your perfect business idea today – https://bw1.in/1111

Conclusion

Starting a notebook manufacturing business requires careful planning, execution, and a commitment to quality. By following these steps and focusing on customer satisfaction, you can build a successful and profitable venture. The Indian market offers significant opportunities, and with the right strategies, you can establish a strong foothold in this industry.

Frequently Asked Questions (FAQs)

- What is the initial investment required to start a notebook manufacturing business?

- The initial investment can vary significantly, ranging from ₹5 lakhs to ₹50 lakhs or more, depending on the scale of operation and the machinery used.

- What are the essential machines needed for notebook manufacturing?

- Essential machines include paper cutting machines, printing machines (optional), binding machines, and packaging machines.

- How can I source high-quality raw materials for notebook manufacturing?

- Source raw materials from reputable suppliers, considering factors like quality, GSM, and cost.

- What are the key marketing strategies for a notebook manufacturing business?

- Key strategies include online sales, partnerships with retailers, direct sales to institutions, and promotional activities.

- What are the legal requirements for starting a notebook manufacturing business in India?

- Legal requirements include business registration, obtaining necessary licenses and permits, and GST registration.

- How can I ensure quality control in notebook manufacturing?

- Implement rigorous quality checks at every stage of the manufacturing process and collect customer feedback.

- What are the profit margins in the notebook manufacturing business?

- Profit margins can vary, but generally range from 15% to 30%, depending on the efficiency of operations and sales strategies.

- How can I compete with established notebook brands?

- Focus on quality, offer competitive pricing, provide excellent customer service, and build a strong brand identity.