Table of contents

- Why Jump into 3D Printing Manufacturing?

- Key Cost Factors

- 1. Defining Your Niche and Market Research: The Cornerstone of Success

- 2. Business Planning and Setup: Laying a Solid Foundation

- 3. Building a Robust Online Presence: Reaching Your Target Audience

- 4. Manufacturing and Operations: Ensuring Efficiency and Quality

- 5. Marketing and Sales: Driving Revenue Growth

- Need Expert Guidance?

- Conclusion

- Frequently Asked Questions (FAQs)

The world of manufacturing is evolving, and 3D printing, also known as additive manufacturing, is leading the charge. If you’re looking to start a modern, scalable business, a 3D printing manufacturing business offers immense potential. This article will guide you through the essential steps, leveraging SEO best practices to ensure your online presence thrives.

Why Jump into 3D Printing Manufacturing?

You Can Make Things People Really Want:

- 3D printing lets you make custom stuff. This means you can create things that fit exactly what someone needs. Think special tools for a factory, or a perfect-fit part for a machine. You’re not just making standard items; you’re solving problems.

- People love things made just for them. You can make personalized items, like phone cases with names, or custom jewelry. This kind of personal touch is very popular.

It’s Cheaper and Faster:

- Traditional manufacturing can be expensive and slow. You need big factories and lots of tools. 3D printing cuts down on those costs.

- You can make prototypes (test versions) quickly. This helps companies test ideas and make changes faster, saving time and money.

- For small production runs, or one off items, 3d printing is often much cheaper than traditional manufacturing.

You Can Work From Almost Anywhere:

- You don’t need a huge factory to start. With the right 3D printers and software, you can work from a small workshop or even your home.

- You can sell your products online, reaching customers all over India and even the world.

The Demand is Growing:

- More and more industries are using 3D printing. From making parts for cars and airplanes to creating medical implants, the uses are endless.

- In India, the government is pushing for more local manufacturing (“Make in India”). This means more opportunities for businesses like yours.

- The healthcare industry in India is rapidly adopting 3d printing for custom prosthesis, and other applications.

You Can Be Creative and Innovative:

- 3D printing lets you design and make things that weren’t possible before. You can experiment with new materials and designs.

- You can create unique products that stand out from the crowd. This gives you a competitive edge.

You Can Start Small and Grow Big:

- You don’t need a lot of money to start. You can begin with a few 3D printers and grow your business as you get more customers.

- As your business grows, you can add more printers, hire people, and expand your product line.

It’s a Future-Proof Skill:

- 3D printing is a technology that’s here to stay. As it gets better and cheaper, more industries will use it.

- Learning 3D printing skills now will give you a valuable advantage in the future.

In Simple Terms:

- You can make cool, custom stuff.

- It’s often cheaper and faster than old ways of making things.

- You can work from almost anywhere.

- Lots of people want 3D printed products.

- You can be super creative.

- You can start small and grow big.

- It’s a skill that will be very valuable in the future.

Key Cost Factors

- 3D Printers:

- The cost of 3D printers varies significantly depending on the technology (FDM, SLA, SLS), quality, and intended use.

- Entry-level desktop FDM printers can range from a few hundred to a few thousand dollars.

- Industrial-grade printers, especially those for metal or advanced polymer printing, can cost tens or even hundreds of thousands of dollars.

- When starting, it’s prudent to invest in reliable mid-range printers that meet your immediate production needs.

- Materials:

- Filament (for FDM), resin (for SLA), or powder (for SLS) costs will depend on the type and quantity of materials you use.

- Specialty materials, such as biocompatible resins or high-temperature filaments, are generally more expensive.

- It’s important to factor in the cost of initial material stock and ongoing material purchases.

- Software:

- CAD software for 3D modeling and slicing software for preparing models for printing are essential.

- Some software is available through subscription, while others require a one-time license purchase.

- Open-source software can be a cost-effective option for beginners.

- Post-Processing Equipment:

- Depending on your products, you may need equipment for sanding, painting, curing, or other post-processing steps.

- These costs can range from basic tools to specialized equipment.

- Workspace and Utilities:

- The cost of renting or setting up a workspace will vary depending on your location and the size of your operation.

- Utilities, such as electricity and internet, should also be factored into your budget.

- Marketing and Branding:

- Developing a website, creating marketing materials, and online advertising can add to your startup costs.

- Building a strong online presence is essential for attracting customers.

- Legal and Licensing:

- Business registration, permits, and licenses are necessary legal requirements.

- It’s advisable to consult with a legal professional to ensure compliance.

Investment Considerations

- Initial Investment:

- The total initial investment can vary widely, from a few thousand dollars for a small-scale operation to tens of thousands of dollars for a larger, more specialized business.

- It’s crucial to create a detailed budget and financial forecast.

- Funding Sources:

- Personal savings, loans, and investors are potential funding sources.

- In India, government initiatives and MSME schemes may offer financial assistance.

- Phased Investment:

- Consider a phased investment approach, starting with essential equipment and gradually expanding as your business grows.

Important Notes:

- Thorough market research and a solid business plan are essential before investing.

- It’s important to factor in ongoing operating costs, such as material purchases, maintenance, and marketing.

- It is wise to seek out any local or national business grants that could be available.

Here are the steps to start your 3D printing Manufacturing Business

1. Defining Your Niche and Market Research: The Cornerstone of Success

- Niche Specialization:

- Medical Implants & Prosthetics: In India, the demand for personalized medical solutions is rising. Partner with hospitals or orthopedic clinics. Focus on biocompatible materials and precision.

- Aerospace & Automotive Components: These sectors require high-strength, lightweight parts. Target manufacturers and offer rapid prototyping and low-volume production.

- Custom Tooling & Jigs: Offer specialized tools for manufacturing processes, reducing lead times and costs.

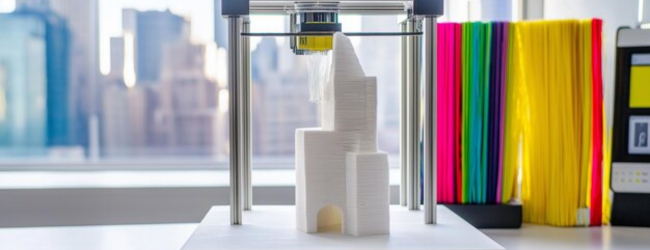

- Architectural Models & Scale Models: Cater to architects, designers, and real estate developers with detailed, accurate models.

- Consumer Goods Customization: Offer personalized products like phone cases, jewelry, or home décor through an online store.

- Detailed Market Analysis:

- Competitive Landscape: Identify competitors, analyze their pricing, product offerings, and marketing strategies. Use tools like SEMrush or Ahrefs to analyze their online presence.

- Target Audience Segmentation:

- Engineers and designers: Focus on technical specifications and rapid prototyping capabilities.

- Medical professionals: Emphasize biocompatibility and precision.

- Consumers: Highlight customization and design options.

- Industrial buyers: stress quality, and volume production.

- Demand Forecasting: Research market reports and industry publications to estimate demand for your chosen niche.

- Market Specifics:

- Government initiatives like “Make in India” are promoting domestic manufacturing.

- The rise of e-commerce is creating opportunities for personalized consumer goods.

- The increasing adoption of Industry 4.0 technologies is driving demand for 3D printing in manufacturing.

- Advanced Keyword Strategy:

- Use semantic SEO to target related keywords and phrases.

- Analyze competitor keywords to identify opportunities.

- Utilize Google Trends to identify trending topics.

- Use question based keywords such as “Where to get custom 3d printed parts in [city name]?”

2. Business Planning and Setup: Laying a Solid Foundation

- Comprehensive Business Plan:

- SWOT Analysis: Identify your strengths, weaknesses, opportunities, and threats.

- Detailed Financial Projections: Include startup costs, operating expenses, revenue projections, and break-even analysis.

- Risk Management Plan: Identify potential risks and develop mitigation strategies.

- Legal and Regulatory Compliance:

- GST registration and compliance.

- Intellectual property protection for your designs.

- MSME registration benefits: priority lending, subsidies and government tenders.

- Product liability insurance.

- Equipment Selection and Optimization:

- Printer Calibration and Maintenance: Regular calibration and maintenance are crucial for consistent quality.

- Material Compatibility: Ensure your printers are compatible with the materials you plan to use.

- Software Integration: Choose CAD and slicing software that integrates seamlessly with your printers.

- Post processing equipment selection: Sanding, painting, chemical baths, UV curing.

- Supply Chain Management:

- Establish relationships with reliable material suppliers.

- Implement inventory management systems to track stock levels.

- Optimize logistics for efficient shipping and delivery.

3. Building a Robust Online Presence: Reaching Your Target Audience

- Website Optimization:

- Schema Markup: Implement schema markup to enhance search engine understanding of your content.

- Content Localization: If targeting specific regions, localize your website content.

- Accessibility: Ensure your website is accessible to users with disabilities.

- Implement Conversion Rate Optimization (CRO) strategies.

- E-commerce Strategies:

- Product Photography and Videography: High-quality visuals are essential for online sales.

- Customer Reviews and Testimonials: Build trust and credibility with customer reviews.

- Personalized Recommendations: Use data to provide personalized product recommendations.

- Offer multiple payment and shipping options.

- Social Media Engagement:

- Create engaging video content showcasing your products and processes.

- Run targeted social media advertising campaigns.

- Engage with your audience through comments and messages.

- Utilize social media analytics to optimize performance.

- Local SEO (for physical locations):

- Optimize your Google My Business profile with accurate information and high-quality photos.

- Encourage customer reviews on Google Maps.

- Build local citations in relevant directories.

💡 Pro Tip: If you want to start a business but have too many doubts, connect with a food business expert from Boss Wallah for guidance – https://bw1.in/1116

4. Manufacturing and Operations: Ensuring Efficiency and Quality

- Material Testing and Analysis:

- Conduct material testing to ensure compliance with industry standards.

- Analyze material properties to optimize product design.

- Quality Management Systems:

- Implement ISO 9001 or other relevant quality management systems.

- Use statistical process control (SPC) to monitor and improve manufacturing processes.

- Automation and Optimization:

- Invest in automation technologies to increase efficiency and reduce costs.

- Use data analytics to optimize manufacturing processes.

- Sustainable Manufacturing Practices:

- Use recycled materials.

- Minimize waste.

- Optimize energy consumption.

5. Marketing and Sales: Driving Revenue Growth

- Content Marketing Strategy:

- Create in-depth case studies showcasing successful projects.

- Develop educational webinars and online courses.

- Publish white papers and industry reports.

- Create a blog that adresses common 3d printing problems and solutions.

- Sales Strategies:

- Develop a sales funnel to guide potential customers through the buying process.

- Offer customized solutions and value-added services.

- Build strong relationships with key customers.

- Partnership and Collaboration:

- Partner with design firms, engineering companies, and other businesses in related industries.

- Attend industry events and trade shows to network and generate leads.

- Customer Relationship Management (CRM):

- Use a CRM system to track customer interactions and manage leads.

- Provide excellent customer service to build loyalty.

By implementing these detailed strategies, you can build a thriving and profitable 3D printing manufacturing business.

Need Expert Guidance?

Starting a business can be challenging, but you don’t have to do it alone! At Boss Wallah, our 2,000+ business experts are ready to provide valuable insights and guidance. Whether you need help with marketing, finance, sourcing, or any other area of any business, our business experts are here to help you succeed- https://bw1.in/1116

Confused about Which Business to Start?

Want to start your own business but unsure which one to choose? Explore Boss Wallah, where you’ll find 500+ courses by successful business owners, featuring practical, step-by-step guides on starting and growing various businesses.

Find your perfect business idea today – https://bw1.in/1111

Conclusion

Starting a 3D printing manufacturing business requires careful planning, dedication, and a strong online presence. By following these steps and implementing effective SEO strategies, you can build a successful and profitable venture. The 3D printing industry is continuously evolving, offering exciting opportunities for innovation and growth.

Frequently Asked Questions (FAQs)

- What are the initial costs of starting a 3D printing manufacturing business?

- Costs vary depending on the scale and niche but typically include equipment, materials, software, and marketing expenses.

- What types of 3D printers are best for manufacturing?

- Industrial-grade FDM or resin printers are often preferred for manufacturing due to their accuracy and reliability.

- What materials are commonly used in 3D printing manufacturing?

- PLA, ABS, PETG, resins, and metals are commonly used materials.

- How do I find customers for my 3D printing manufacturing business?

- Online marketing, networking, and partnerships are effective strategies.

- What are the legal requirements for starting a 3D printing manufacturing business in India?

- You’ll need to register your business, obtain necessary licenses, and comply with relevant regulations.

- How do I ensure quality control in 3D printing manufacturing?

- Implement rigorous testing and measurement procedures, and use high-quality materials.

- What are the future trends in 3D printing manufacturing?

- Increased automation, advanced materials, and integration with Industry 4.0 technologies are key trends.

- How can I scale my 3D printing manufacturing business?

- By investing in more equipment, expanding your team, and diversifying your product offerings.