Table of contents

- 1. Sustainable Packaging Solutions

- 2. Custom 3D Printed Industrial Parts

- 3. Smart Sensor Manufacturing

- 4. Advanced Composite Materials

- 5. Industrial Automation Systems

- 6. Medical Device Manufacturing

- 7. Renewable Energy Components

- 8. Precision Machining Services

- 9. Industrial Cleaning and Sanitation Solutions

- 10. Custom Industrial Tooling and Fixtures

- Need Expert Guidance?

- Conclusion

- Frequently Asked Questions (FAQs)

The landscape of B2B manufacturing is constantly evolving, driven by technological advancements, sustainability concerns, and shifting market demands. As we look towards 2025, several promising opportunities are emerging for entrepreneurs ready to capitalize on these trends. Here are 10 high-demand B2B manufacturing business ideas that are poised for success:

1. Sustainable Packaging Solutions

Manufacturing eco-friendly packaging materials like biodegradable plastics, compostable containers, and recycled paper products to meet the increasing demand for sustainable solutions.

- a. Why this Idea: Growing environmental awareness and stricter regulations are driving businesses to adopt sustainable packaging.

- b. Licenses Required: Environmental permits, manufacturing licenses, and potentially food-grade certifications.

- c. Investment Required: Moderate to high, depending on the scale and technology used.

- d. How to Sell: Target food and beverage companies, e-commerce businesses, and other industries seeking sustainable packaging.

- e. Any other Requirements: Focus on R&D to develop innovative and cost-effective sustainable materials.

- f. Challenges in the Idea: High initial setup costs, competition from established players, and ensuring material quality.

- g. How to overcome the Challenges: Focus on niche markets, build strong partnerships with suppliers, and emphasize unique selling propositions.

- h. Example: A company that manufactures packaging materials from agricultural waste, creating custom-designed, compostable containers for food delivery services.

2. Custom 3D Printed Industrial Parts

Providing on-demand manufacturing of custom industrial parts using advanced 3D printing technologies for various sectors.

- a. Why this Idea: Reduces lead times, minimizes waste, and enables rapid prototyping and production of complex parts.

- b. Licenses Required: Manufacturing licenses, potentially industry-specific certifications (e.g., aerospace, medical).

- c. Investment Required: High, due to specialized 3D printers and materials.

- d. How to Sell: Target aerospace, automotive, medical device, and engineering companies.

- e. Any other Requirements: Skilled engineers and technicians, advanced software for design and simulation.

- f. Challenges in the Idea: High equipment costs, material limitations, and ensuring dimensional accuracy.

- g. How to overcome the Challenges: Focus on specialized applications, invest in high-quality equipment, and build a strong online presence.

- h. Example: A business offering rapid prototyping and small-batch production of custom metal parts for the automotive industry, using advanced metal 3D printing.

3. Smart Sensor Manufacturing

Producing smart sensors for IoT applications in industries like agriculture, healthcare, and manufacturing.

- a. Why this Idea: Growing demand for real-time data and automation in various sectors.

- b. Licenses Required: Manufacturing licenses, electronic component certifications.

- c. Investment Required: Moderate to high, depending on the complexity of the sensors.

- d. How to Sell: Target IoT solution providers, industrial automation companies, and smart agriculture businesses.

- e. Any other Requirements: Expertise in electronics, software development, and data analytics.

- f. Challenges in the Idea: Rapid technological advancements, ensuring data security, and interoperability issues.

- g. How to overcome the Challenges: Invest in continuous R&D, implement robust security measures, and adhere to industry standards.

- h. Example: A company manufacturing wireless sensors for monitoring soil moisture and nutrient levels in large-scale agricultural operations.

💡 Pro Tip: If you want to start a home-based business but have too many doubts, connect with a home-based business expert from Boss Wallah for guidance – https://bw1.in/1116

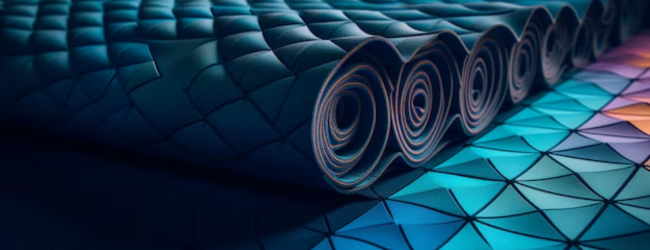

4. Advanced Composite Materials

Manufacturing high-performance composite materials for industries like aerospace, automotive, and construction.

- a. Why this Idea: Demand for lightweight, strong, and durable materials in various applications.

- b. Licenses Required: Manufacturing licenses, industry-specific certifications (e.g., aerospace).

- c. Investment Required: High, due to specialized equipment and materials.

- d. How to Sell: Target aerospace manufacturers, automotive companies, and construction firms.

- e. Any other Requirements: Skilled engineers, advanced manufacturing processes.

- f. Challenges in the Idea: High material costs, complex manufacturing processes, and quality control.

- g. How to overcome the Challenges: Focus on high-value applications, optimize manufacturing processes, and implement rigorous quality control.

- h. Example: A company producing carbon fiber composite components for aircraft wings, offering superior strength and weight reduction.

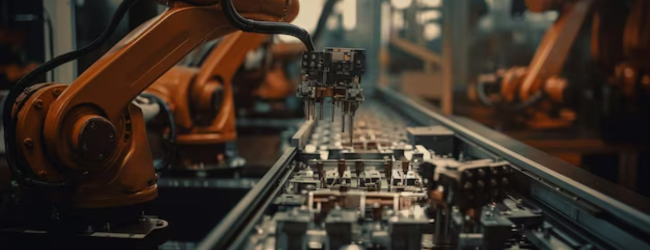

5. Industrial Automation Systems

Designing and manufacturing custom industrial automation systems for various manufacturing processes.

- a. Why this Idea: Increasing demand for automation to improve efficiency and reduce labor costs.

- b. Licenses Required: Manufacturing licenses, electrical and mechanical certifications.

- c. Investment Required: High, due to specialized equipment and software.

- d. How to Sell: Target manufacturing plants, logistics companies, and industrial automation integrators.

- e. Any other Requirements: Skilled engineers, software developers, and system integrators.

- f. Challenges in the Idea: Complex integration, ensuring system reliability, and rapid technological advancements.

- g. How to overcome the Challenges: Build strong partnerships with technology providers, invest in continuous training, and prioritize system reliability.

- h. Example: A business designing and manufacturing automated robotic systems for packaging and palletizing in food processing plants.

6. Medical Device Manufacturing

Producing specialized medical devices and equipment for hospitals and healthcare providers.

- a. Why this Idea: Growing healthcare sector and increasing demand for advanced medical technologies.

- b. Licenses Required: FDA approvals, ISO certifications, and manufacturing licenses.

- c. Investment Required: High, due to strict regulatory requirements and specialized equipment.

- d. How to Sell: Target hospitals, clinics, and medical device distributors.

- e. Any other Requirements: Strict adherence to regulatory standards, skilled engineers, and quality control.

- f. Challenges in the Idea: Stringent regulatory requirements, high R&D costs, and product liability.

- g. How to overcome the Challenges: Build a strong regulatory team, invest in robust quality management systems, and focus on niche markets.

- h. Example: A company manufacturing custom-designed prosthetics using advanced 3D printing and biomechanical engineering.

7. Renewable Energy Components

Manufacturing components for renewable energy systems, such as solar panels, wind turbine blades, and energy storage solutions.

- a. Why this Idea: Growing demand for renewable energy sources and government incentives.

- b. Licenses Required: Manufacturing licenses, environmental permits, and industry-specific certifications.

- c. Investment Required: High, due to specialized equipment and materials.

- d. How to Sell: Target renewable energy project developers, solar installers, and wind farm operators.

- e. Any other Requirements: Skilled engineers, advanced manufacturing processes, and quality control.

- f. Challenges in the Idea: High material costs, technological advancements, and competition from established players.

- g. How to overcome the Challenges: Focus on innovative materials, optimize manufacturing processes, and build strong partnerships.

- h. Example: A business manufacturing high-efficiency solar panels using advanced thin-film technology.

ALSO READ | Funding for Small Business: Your Guide to Securing Capital in 2025

8. Precision Machining Services

Providing precision machining services for manufacturing complex parts with tight tolerances.

- a. Why this Idea: Demand for high-precision components in industries like aerospace, automotive, and medical.

- b. Licenses Required: Manufacturing licenses, industry-specific certifications.

- c. Investment Required: Moderate to high, due to specialized CNC machines.

- d. How to Sell: Target engineering firms, manufacturing companies, and research institutions.

- e. Any other Requirements: Skilled machinists, CAD/CAM software, and quality control equipment.

- f. Challenges in the Idea: High equipment costs, skilled labor shortage, and competition from established shops.

- g. How to overcome the Challenges: Invest in advanced CNC machines, offer specialized services, and build a strong reputation for quality.

- h. Example: A company offering high-precision CNC machining services for manufacturing custom components for aerospace engines, ensuring tight tolerances and high-quality finishes.

9. Industrial Cleaning and Sanitation Solutions

Manufacturing specialized cleaning and sanitation products and equipment for industrial settings, focusing on hygiene and safety.

- a. Why this Idea: Increasing emphasis on workplace hygiene and safety, especially in food processing and healthcare industries.

- b. Licenses Required: Manufacturing licenses, environmental permits, and potentially industry-specific certifications (e.g., food safety).

- c. Investment Required: Moderate, depending on the scale and complexity of the products.

- d. How to Sell: Target food processing plants, pharmaceutical companies, hospitals, and industrial cleaning service providers.

- e. Any other Requirements: Expertise in chemistry, microbiology, and safety regulations.

- f. Challenges in the Idea: Competition from established chemical companies, ensuring product efficacy, and compliance with safety regulations.

- g. How to overcome the Challenges: Focus on niche markets, develop innovative and eco-friendly products, and build a strong reputation for quality and reliability.

- h. Example: A company manufacturing specialized antimicrobial cleaning solutions and automated sanitation equipment for food processing plants, ensuring compliance with strict hygiene standards.

10. Custom Industrial Tooling and Fixtures

Designing and manufacturing custom tooling, jigs, and fixtures for various manufacturing processes, improving efficiency and accuracy.

- a. Why this Idea: Demand for customized solutions to optimize manufacturing processes and reduce production costs.

- b. Licenses Required: Manufacturing licenses, and potentially industry-specific certifications.

- c. Investment Required: Moderate to high, due to specialized design software and manufacturing equipment.

- d. How to Sell: Target manufacturing plants, automotive companies, and aerospace manufacturers.

- e. Any other Requirements: Skilled engineers, CAD/CAM software, and precision machining capabilities.

- f. Challenges in the Idea: Complex design and manufacturing processes, ensuring dimensional accuracy, and meeting tight deadlines.

- g. How to overcome the Challenges: Invest in advanced design and manufacturing technologies, build a team of experienced engineers, and implement rigorous quality control measures.

- h. Example: A business designing and manufacturing custom robotic welding fixtures for automotive assembly lines, improving efficiency and precision.

Need Expert Guidance?

Starting a business can be challenging, but you don’t have to do it alone! At Boss Wallah, our 2,000+ business experts are ready to provide valuable insights and guidance. Whether you need help with marketing, finance, sourcing, or any other area of any business, our business experts are here to help you succeed- https://bw1.in/1116

Confused about Which Business to Start?

Want to start your own business but unsure which one to choose? Explore Boss Wallah, where you’ll find 500+ courses by successful business owners, featuring practical, step-by-step guides on starting and growing various businesses.

Find your perfect business idea today – https://bw1.in/1111

Conclusion

The B2B manufacturing sector in 2025 presents numerous lucrative opportunities for entrepreneurs who are willing to embrace innovation and adapt to evolving market demands. By focusing on sustainability, advanced technologies, and specialized solutions, businesses can position themselves for long-term success. Carefully evaluate your resources, conduct thorough market research, and develop a robust business plan to capitalize on these high-demand manufacturing ideas.

Frequently Asked Questions (FAQs)

1. What are the key trends driving B2B manufacturing in 2025?

- Key trends include sustainability, automation, customization, and the integration of IoT technologies.

2. What are the essential licenses required for starting a manufacturing business?

- Essential licenses typically include manufacturing licenses, environmental permits, and industry-specific certifications (e.g., FDA approvals, ISO certifications).

3. How much investment is needed to start a B2B manufacturing business?

- Investment varies significantly depending on the industry and scale of operation, ranging from moderate to high.

4. How can I effectively market my B2B manufacturing products?

- Effective marketing strategies include targeted online advertising, industry trade shows, networking, and building strong relationships with potential clients.

5. What are the biggest challenges in the B2B manufacturing industry?

- Common challenges include high initial setup costs, competition from established players, regulatory compliance, and technological advancements.

6. How can I overcome the challenges in the B2B manufacturing industry?

- Overcoming challenges involves focusing on niche markets, building strong partnerships, investing in R&D, and implementing robust quality control measures.

7. What is the importance of sustainability in B2B manufacturing?

- Sustainability is crucial due to increasing environmental awareness, stricter regulations, and the growing demand for eco-friendly products.

8. How does automation impact B2B manufacturing?

- Automation improves efficiency, reduces labor costs, and increases production output, making it a critical factor in modern manufacturing.